About Kolver

Founded in 1989, KOLVER has soon taken the leadership in the European market of precision electric screwdrivers for industry.

Thousands of state-of-art drivers are produced every year in italy and then shipped to more than 30 countries worldwide

ISO 9001 Certified since 1998, KOLVER has gained international recognition for building premier quality innovative products that meet or even anticipate the most rigorous customer requirements.

Thanks to their low installation, operating and maintenance costs as well as to their reduced vibration and noise level, KOLVER electric screwdrivers represent the perfect alternative to pneumatic screwdrivers for screws up to M10.

What's advantages of KOLVER

ERGONOMIC

Advanced grip design, light in weight, vibrations within the norms, for maximum operator confort

CLEAN

No air exhaust + No librication = a cleaner environement

FLEXIBLE

From the controller you can adjust the running speed and the slow start duraction. Multi torque models also available for additional functions

ACCURATE

With the electronic shut off mechanism the accuracy is better than +-5% of the pre-set value

FOR EVERY APPLICATION

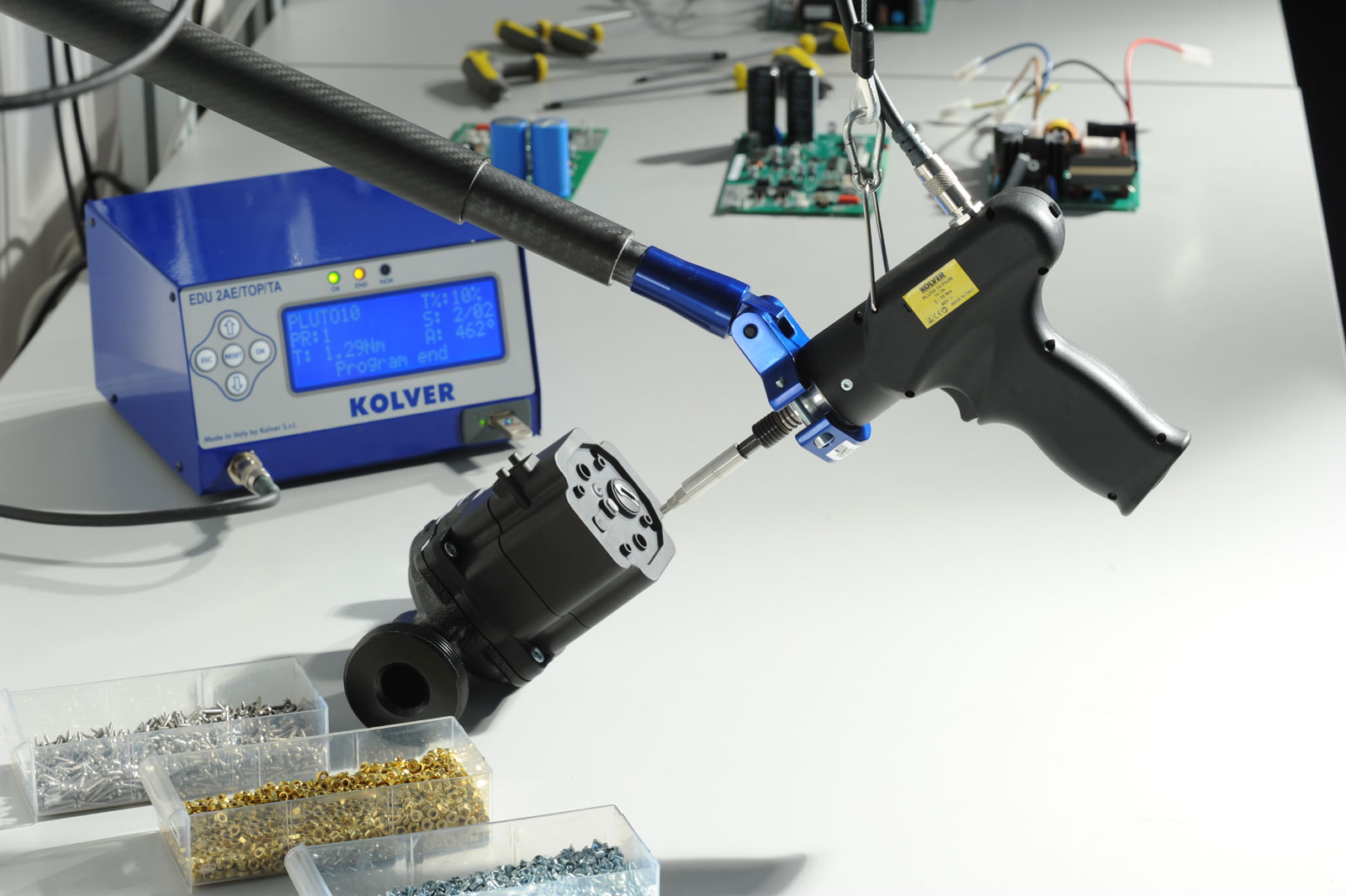

Range up to 50 Nm, straight, pistol, 90°, ESD, with vaccum, lever start or push to start

COST EFFECTIVE

Low purchasing price virtually no maintenace + no need of compressed air line + no need of spiral hoses & couplers & filters & regulators-lubricators = operating cost up to 200 times cheaper than pneumatic screwdrivers.

Informations of Kolver Electric Screwdriver

Manual Screwdrivers

- NATO Series - TORQUE UP TO 50 Ncm ( Ultra-low torque, truly accurate current controlled torque driver designed for applications in which torques below 50 Ncm )

- 1 - 15 Ncm at 350 - 700 RPM

- 5 - 50 Ncm at 200 - 700 RPM

- MITO Series - TORQUE RANGE FROM 0,2 TO 1,5 Nm ( Low torque, truly accurate current controlled torque driver. The MITO features an innovative electric motor coupled with planetary gearbox, producing extremely low inertia and minimal friction for long life. )

- 0,2 - 1,5 Nm at 450 - 850 RPM

- FAB & RAF Series - TORQUE UP TO 5 Nm ( RAF series screwdrivers are designed to meet higher torque application. their advanced ergonomic design, high accuracy and durability. )

- 0,05 - 0,3 Nm at 450 - 650 RPM

- 0,05 - 0,8 Nm at 600 - 1000 RPM

- 0,2 - 1,2 Nm at 600 - 1000 RPM

- 0,3 - 1,8 Nm at 450 - 650 RPM

- 0,7 - 3,2 Nm at 600 - 1000 RPM

- 0,9 - 3,8 Nm at 450 - 650 RPM

- 0,9 - 5,0 Nm at 400 - 700 RPM

- 0,9 - 4,5 Nm at 400 - 700 RPM

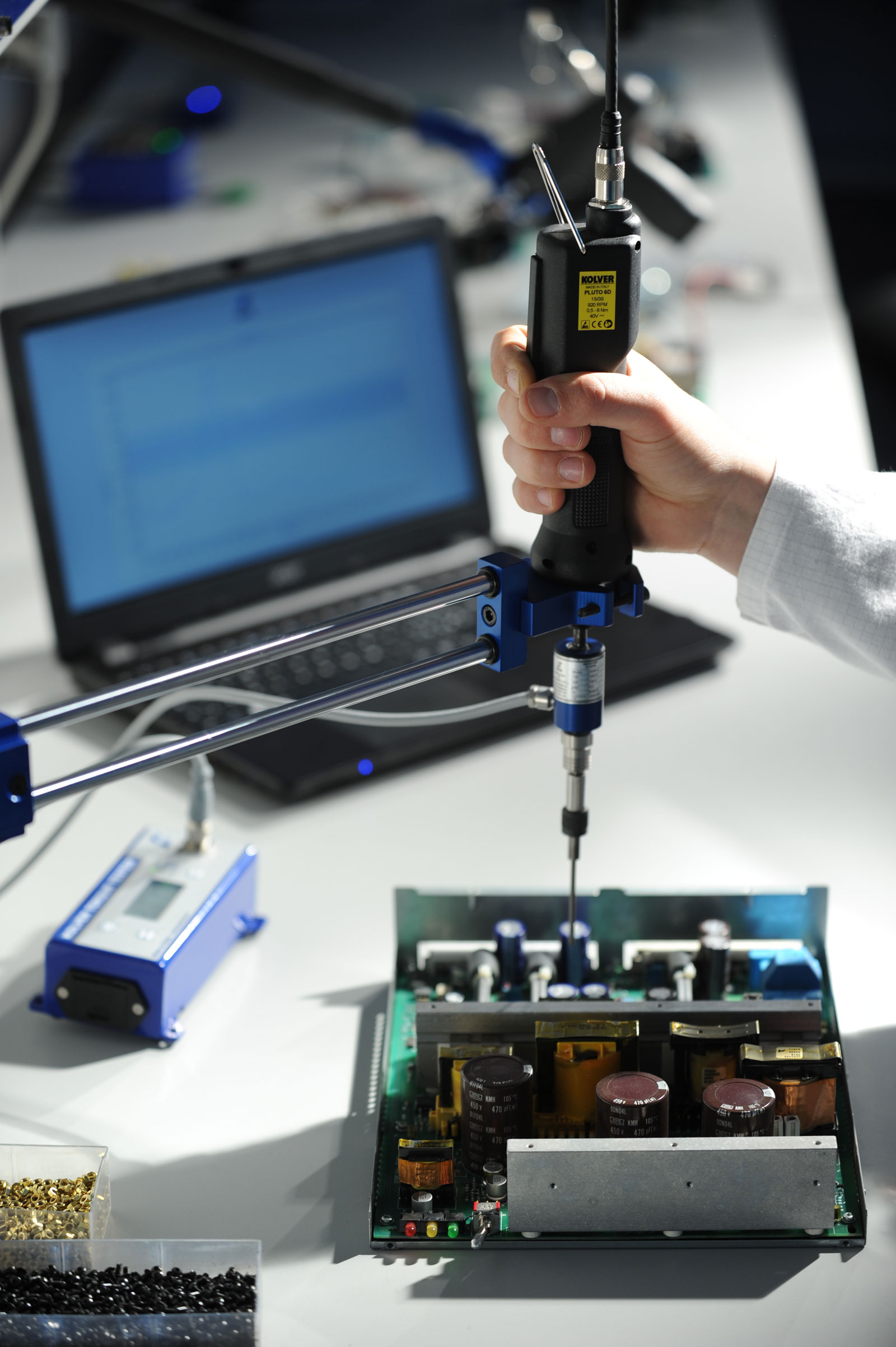

- PLUTO Series - TORQUE UP TO 50 Nm ( PLUS TOrque screwdrivers, the most advanced DC tools in the market, able to reach 50 Nm. They feature an innovative coreless electric motor with low inertia and friction with absence of iron losses for extreme eficiency and extended life. )

- 0,5 - 3,0 Nm at 370 - 1300 RPM

- 0,85 - 6,0 Nm at 200 - 850 RPM

- 1,5 - 10 Nm at 110 - 600 RPM

- 2,0 - 15 Nm at 60 - 320 RPM

- 3,0 - 20 Nm at 50 - 200 RPM

- 5,0 - 50 Nm at 20 - 90 RPM

- PLUTO Clutch Style Series - TORQUE UP TO 7 Nm ( PLUS TOrque screwdrivers Clutch style, Hight-efficiency and low inertia CORELESS motors allow high performances on any kind of joint. The new clutch for the regulation of the tightening torque guarantees and exellent accuracy i.e 3% on the whole range. )

- 0,5 - 3,2 Nm at 800 - 1300 RPM

- 0,7 - 5,0 Nm at 600 - 1000 RPM

- 1,5 - 7,0 Nm at 350 - 600 RPM

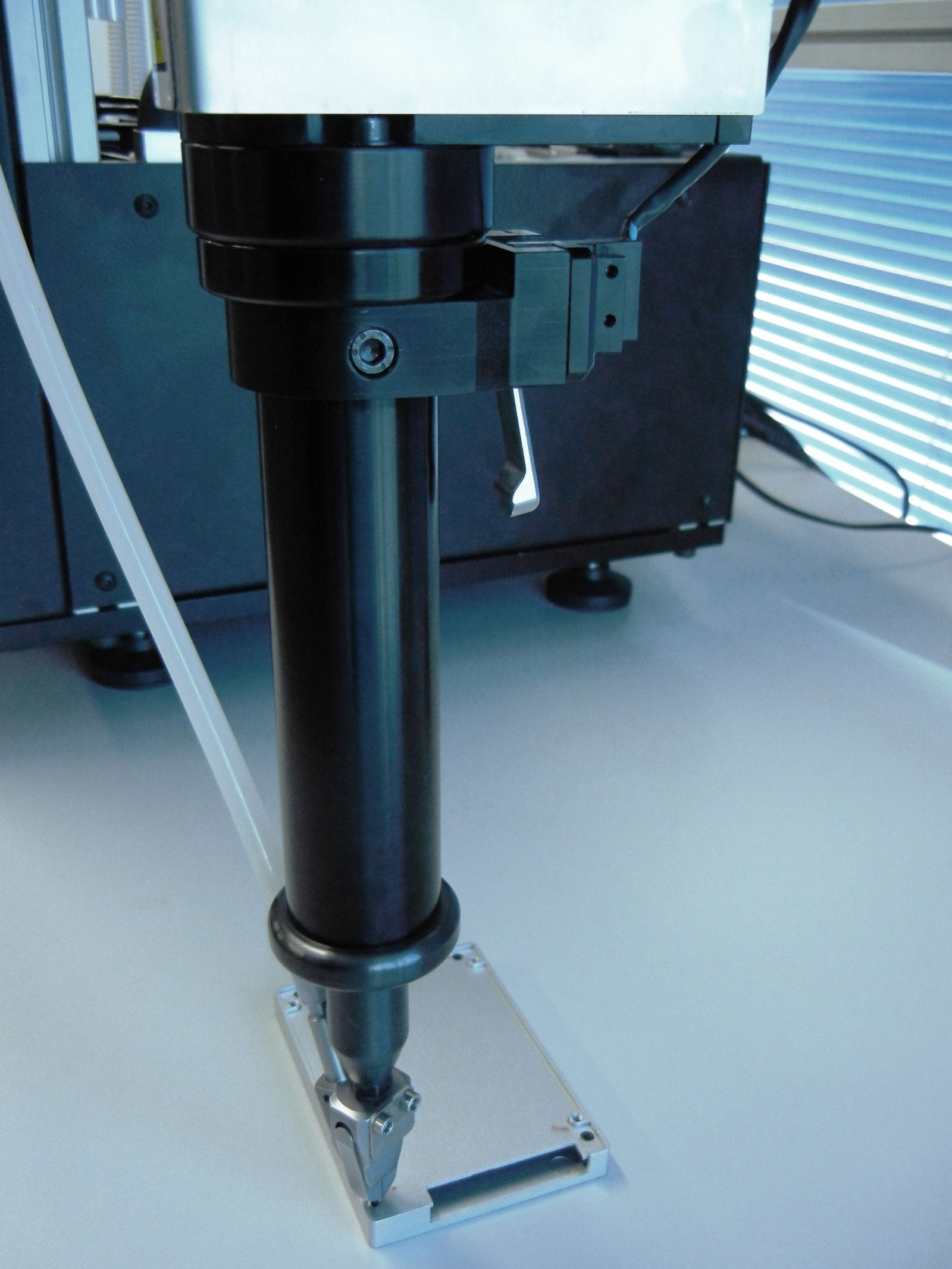

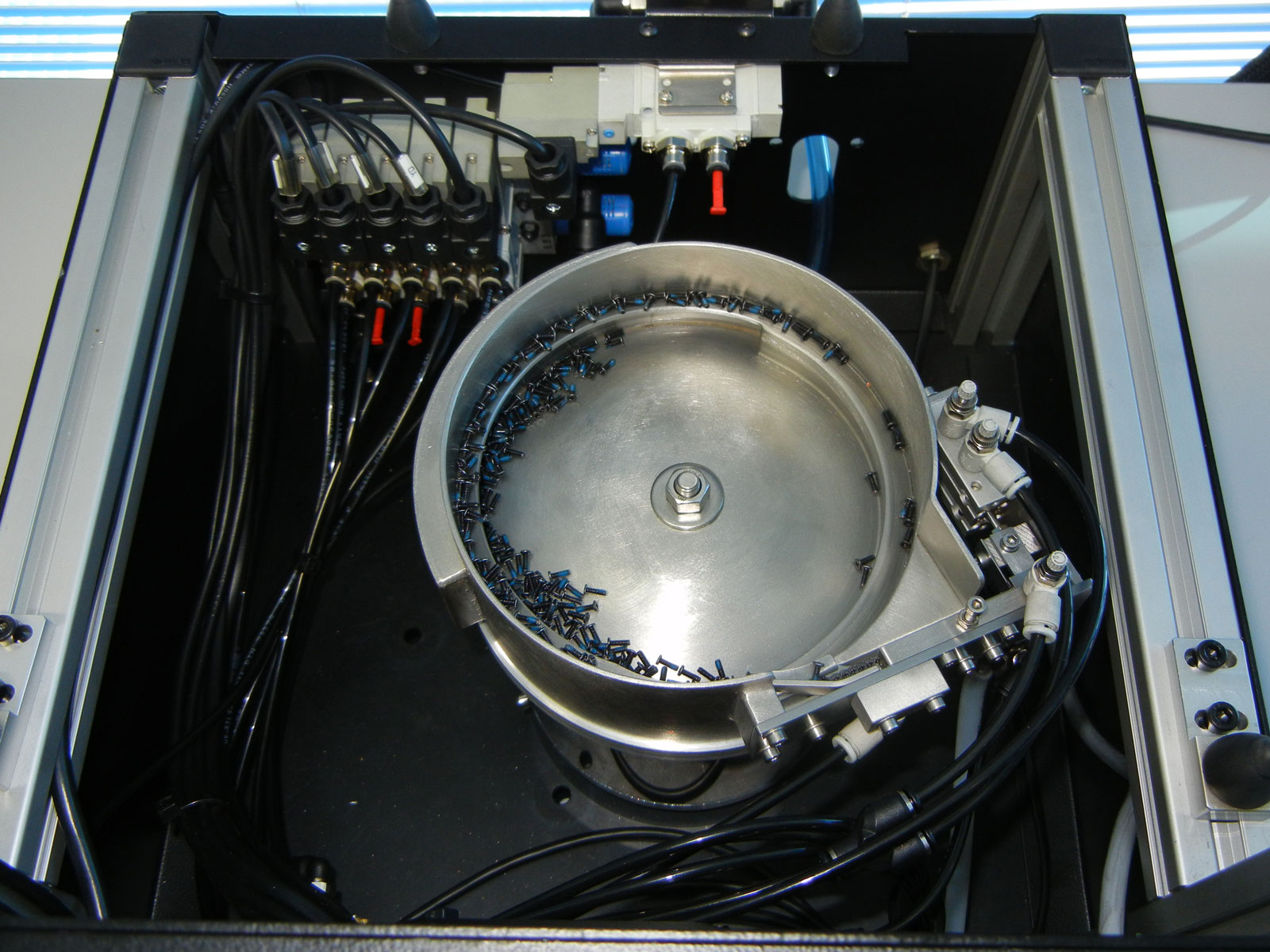

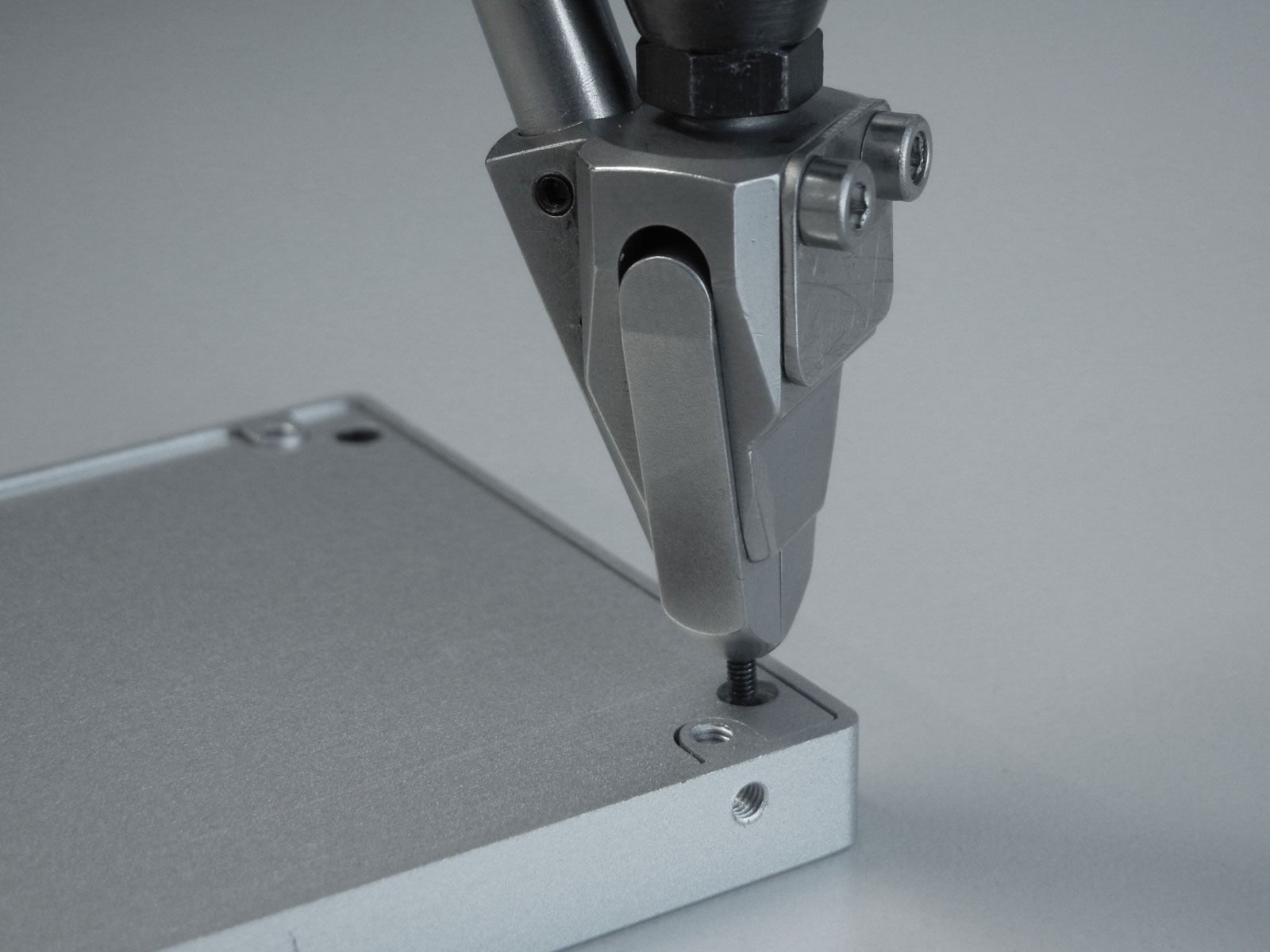

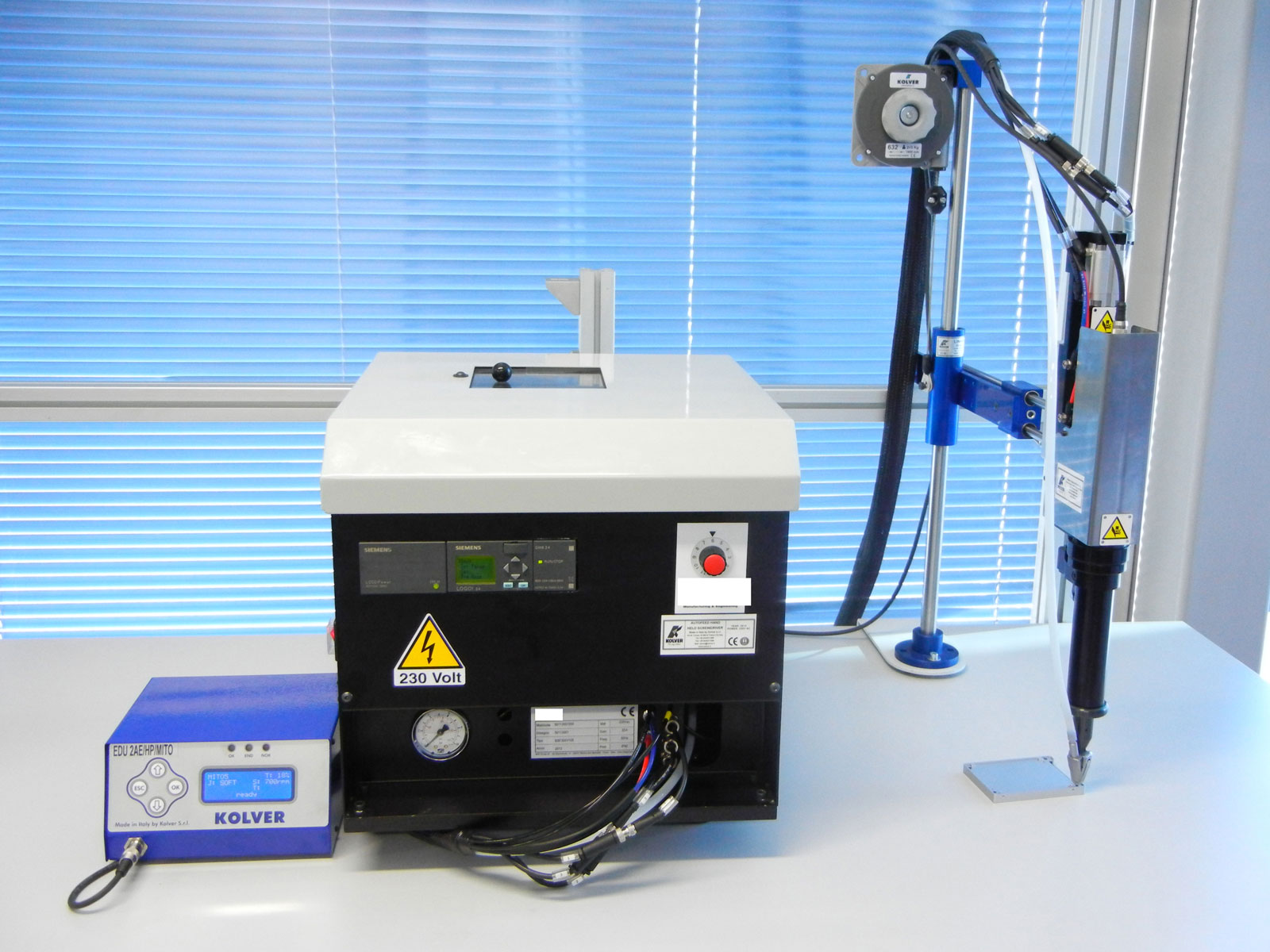

Automatical & Robotical Swcrewdrivers

- CA Series - TORQUE UP TO 50 Nm ( The CA screwdrivers are designed for automated and fixtured application. Special wiring and dedicated controllers are required with electric signals and contacts for immediate and easy interface. The ideal alternative to pneumatic drivers. )

- 0,01 - 0,15 Nm at 350 - 700 RPM

- 0,05 - 0,5 Nm at 200 - 700 RPM

- 0,2 - 1,5 Nm at 450 - 850 RPM

- 0,5 - 3,0 Nm at 370 - 1300 RPM

- 0,85 - 6,0 Nm at 200 - 850 RPM

- 1,5 - 10 Nm at 110 - 600 RPM

- 2,0 - 15 Nm at 60 - 320 RPM

- 3,0 - 20 Nm at 50 - 200 RPM

- 3,0 - 35 Nm at 40 - 140 RPM

- 5,0 - 50 Nm at 20 - 90 RPM

- 0,04 - 0,4 Nm at 650 - 1000 RPM

- 0,4 - 1,5 Nm at 650 - 1000 RPM

- 0,7 - 3,0 Nm at 650 - 1000 RPM

- 0,9 - 4,0 Nm at 450 - 750 RPM