Why make your ESD workstation ?

This lack of reliability can impact the reputation of your company and increase your operating costs, so the process of effectively controlling ESD in your business processes must be one of your major concerns.

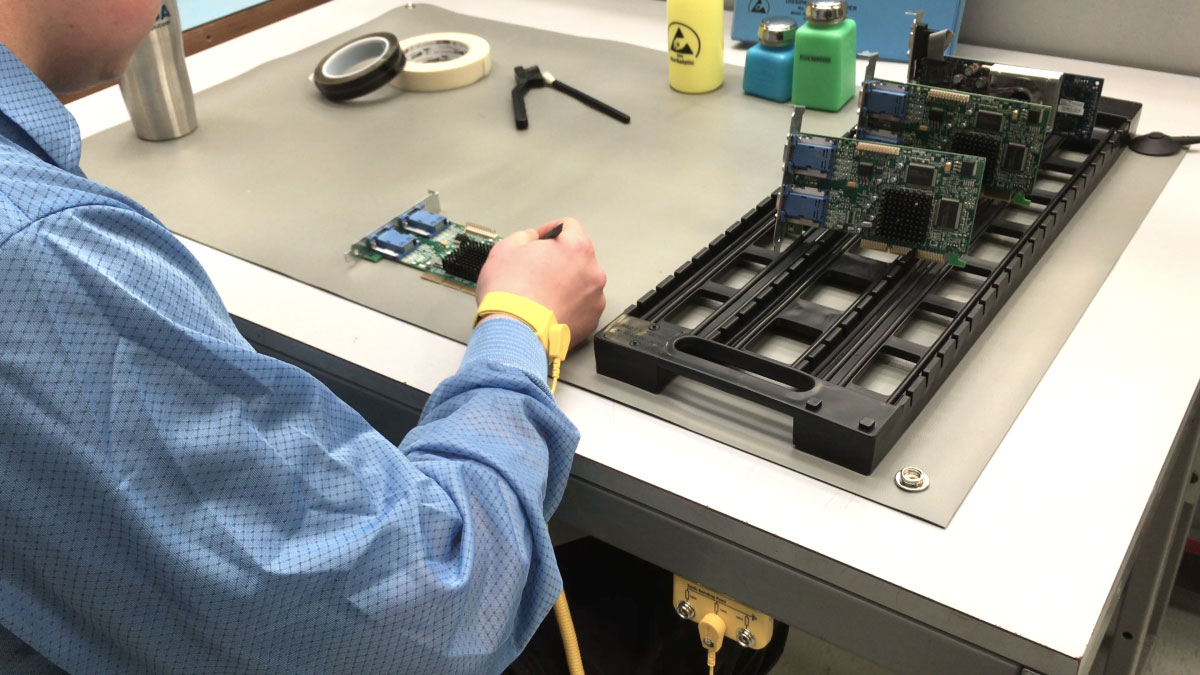

To use antistatic / ESD equipment

In many manufacturing processes, electrostatic charges can cause malfunctions.

Antistatic equipment is used to neutralize static electricity.

This is particularly the case in the semiconductor industry because the components are extremely sensitive and can be damaged by high electrostatic charges.

Discharges can also cause interference in the operation of electronic systems.

Static electricity can generate high voltages (above 10,000 volts and up to 30,000 volts).

A single movement (for example, a person getting up from a chair) can generate a 10,000 volts charge on its own.

Insulating materials create magnetic or electrostatic fields that generate voltages near sensitive electrical circuits and deteriorate by discharging suddenly on the component.

Model and example of ESD clothes

Examples

Other very important information on the ergonomics of work brought by a good work environment

At the end of the manufacturing process, during the prototype testing phase, this type of electrical discharge is applied to the case of the electronic components in order to evaluate their reliability during the handling, handling and assembly.

E.S.D. area : The fragility of most electronic components being such that an electrostatic discharge can damage them, electronic components, cards and subassemblies are handled, handled, assembled and checked in so-called ESD zone

This zone offers a complete absence Isolated electrical charge by using conductive materials at all levels.

The operator himself is in permanent discharge thanks to the use of a conductive bracelet.