Why Fume Extraction ?

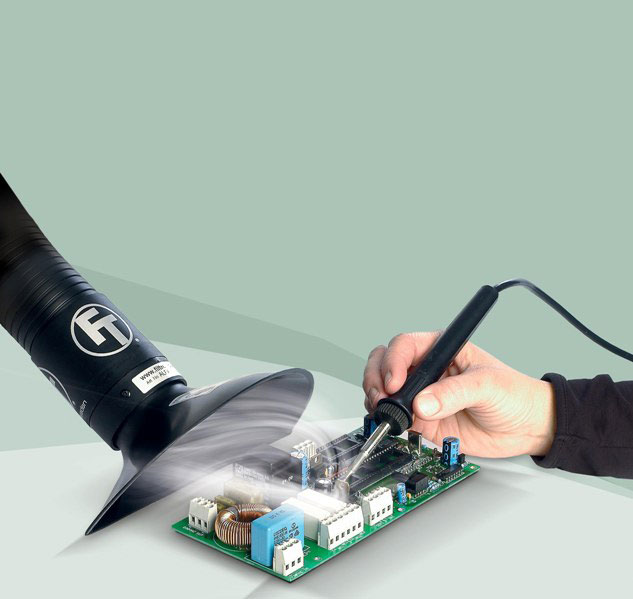

Many work environments today, including soldering and adhesives applications, create particles and gases that can be harmful to the work place and the environment.

To protect the operator, it is important to use an extraction system that is able to separate these particles and gases and then re-circulates the cleaned air back into the work place.

It is important to use the correct safety equipment to remove these hazardous substances.

Inhaling fine particles is more dangerous than big particles that get caught more easily because they can block the alveoli in the lungs.

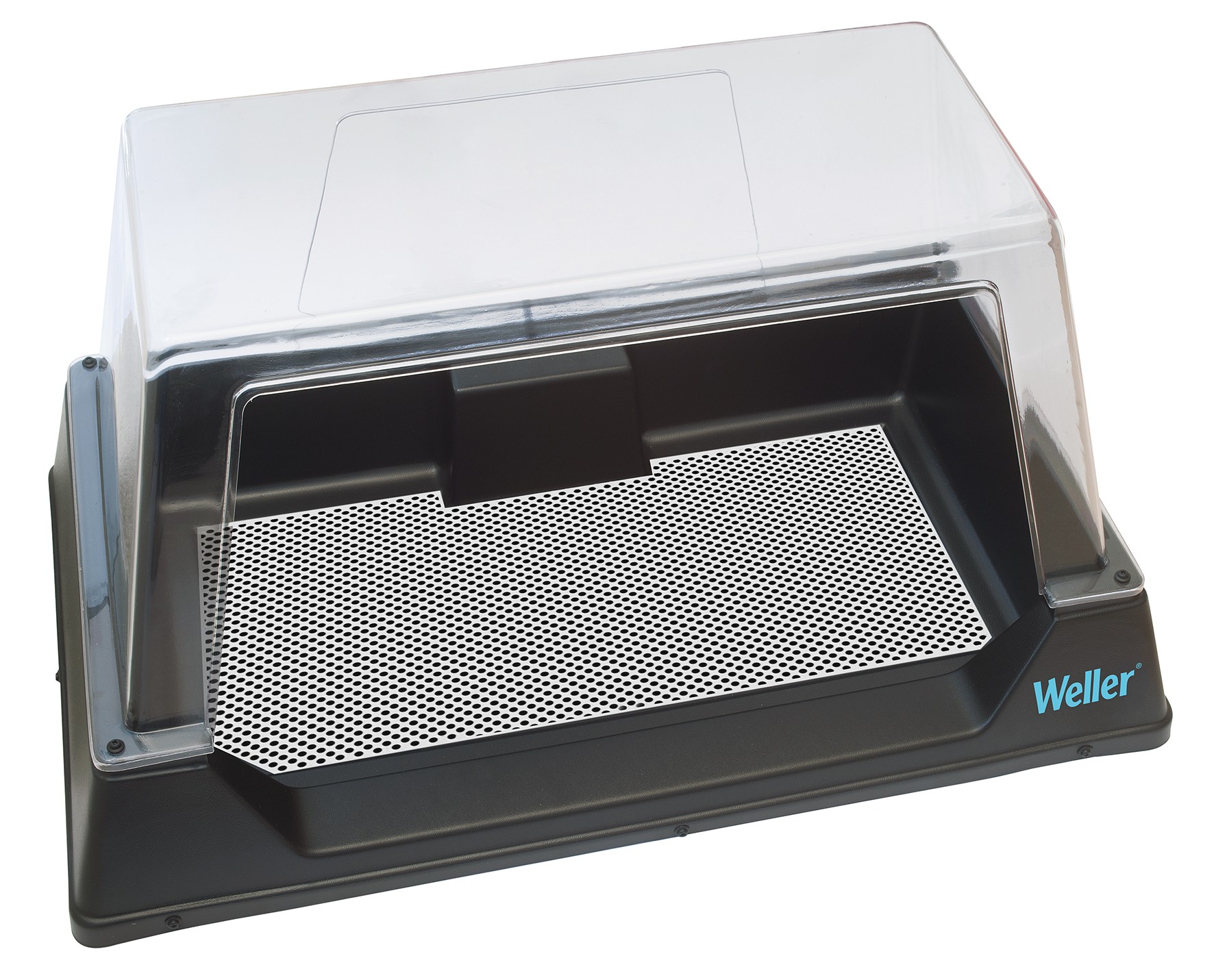

Weller Filtration benefits

- The ultimate protection for the environment, man and machine

- Quick, easy installation thanks to Weller Filtration Easy Click systems

- Long service life thanks to the particularly large filtration areas

- Constant flow control using intelligent control systems

- Quietest equipment in the world

What health risks can develop ?

A lot of todays dust and fumes are hazardous to health when inhaled. Overexposure can lead to serious and long term medical problems such as occupational asthma or other effects like :

- Headaches

- Nosebleeds

- Sionasal cancer

- Sore throat

- Occupational asthma

- Eye irritation

- Dermatitis and acne

- Respiratory damage

The solution for your health

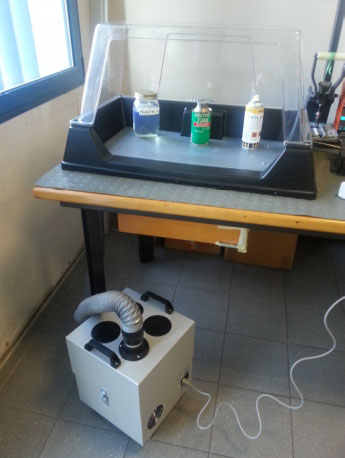

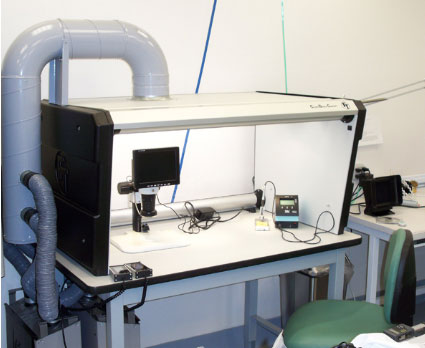

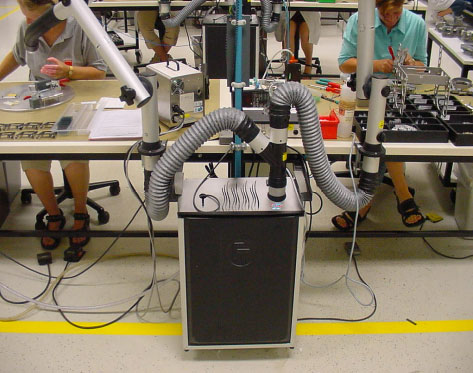

Multi - configuration

10 important things you need to know if you work with hazardous gases and particles !

1 : Long term exposure to airborne particles and gases can couse permanent damage.

2 : Thousands of workers all over the world contract occupational lung and other diseases, including cancer, each year.

They develop those because they breathe in too much dust, fumes or other airborne contaminants at work. *HSE Helath & Safety Executive in Great Britain.

3 : At least 20 % of employees in the soldering area indicate clinical symptoms of asthma. *Results from a study made in USA & Europe

4 : Occupational asthma is a major issue in electronics manufacturing because when a person develops occupational asthma he / she has to be moved from that working area.

5 : Breathing with occupational asthma.

6 : Once a personal develops asthma, the symptoms are permanent and irreversible.

7 : Almost everyone who works in an industrial environement comes in contact with chemicals which contain a solvent.

8 : Most of dangerous gases are invisible to the eye.

9 : For people with heart diseases, short term exposure to hazardous airborne particles, can be linked to heart attacks and abnormal heart rhythms.

10 : The combination of being exposed to both gases and airborne particles is more dangerous than only being exposed to gases.

How do I get the best protection?

- Weller filter systems offer the best possible protection to the operator by extracting dangerous fumes and capturing airborne particles at highest levels.

- The filter systems are mobile, and can be moved around the workplace.

- The systems are easy to install and have low service requirements.

- The noise levels of the filter systems are very low, additionally protecting the operator from excessive noise pollution in manufacturing areas

- The product range consists of various products that can be used for different applications.

- The filters have a long life time.